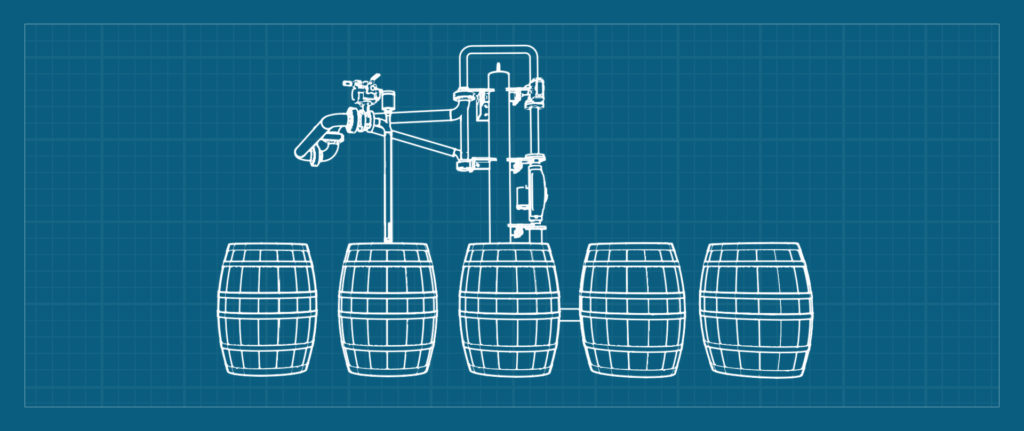

RESEARCHERS at the University of Strathclyde have developed a computer simulation to help whisky distillers fill their casks without spilling any spirit.

As well as the computer program, the engineers built a cask-filling test rig and achieved 99% consistency when filling a 200-litre cask in less than one minute.

Inconsistent cask filling can lead to too much liquid trying to be poured into each barrel, so that some spills over the top, wasting spirit that could mature to become whisky.

Other problems include foaming and under-filling casks, which means that more barrels need to be made and stored, pushing up production costs.

Making the casks accounts for about 10-20% of the overall cost of Scotch production, with distillers like Diageo – Scotland’s biggest whisky maker and the owner of brands including Bell’s, J&B and Johnnie Walker – holding more than 11 million barrels at any one time.

Strathclyde worked on the project with Diageo, technology giant Siemens and process control system firm Kigtek.

The work was funded by Innovate UK, formerly known as the Technology Strategy Board.

Read more whisky news and reviews on Scottish Field’s whisky pages.

TAGS