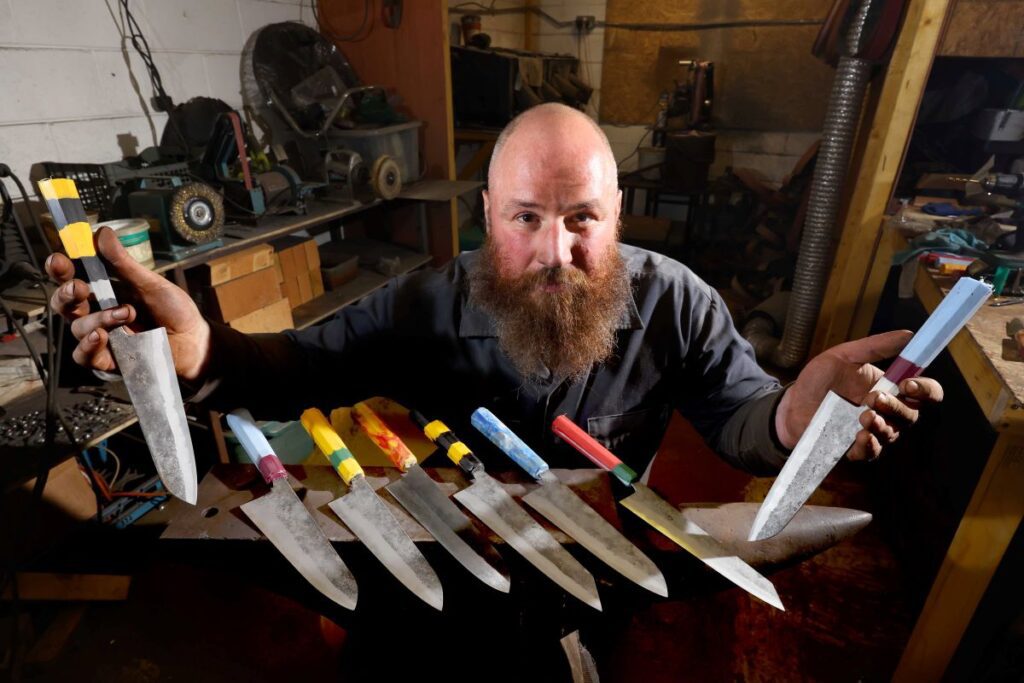

Blademaker using laughing gas canisters and beach litter to make top quality eco friendly knives

As a former professional chef, Tim Westley knows how important having the right knife is.

So it’s not surprising his hand-forged knives – created from highly unusual, recycled materials – are highly prized by some top chefs in the UK.

Tim makes his incredible eco blades at his workshop in Dumfries and Galloway using steel from the tiny NOx (laughing gas) canisters that he collects from places they have been dumped in Glasgow and London.

The colourful handles are made by melting and reshaping plastics from spent shotgun cartridges, provided by estates and shooting ranges, and from items like fish trawler boxes that wash up on local beaches.

The idea for Clement Knives came to Tim when he was living on a narrowboat in London and had a workshop on an island in the Thames.

He used to go out in a canoe collecting litter that was polluting the river and was trying to think of ways it could be positively repurposed.

He was looking for a creative outlet, and after watching a video online abut knife making he decided to give it a go.

Apart from the moulding of the plastic handles, the method he uses to make the knives is very traditional. Most of the techniques and processes Tim use are more than 200 years old and he still relies on tools that predate WW1.

‘A really good knife is so important to people who love cooking – for professional chefs it’s something they can be using just about all day every day,’ Tim said.

‘I’ve worked in some fantastic British restaurants myself, and travelled round Australia working in restaurants, so it’s something I really appreciate.

‘Douglas McMaster, the founder of Silo London, the world’s first Zero Waste restaurant, was the first chef I showed my knives to

and we quickly became friends in our zero waste lifestyles.

‘The knives I make are from materials that I have 95% recycled myself. Each one is made individually using blades I forge here in my workshop.’

‘It’s great that the world is actively looking for businesses and crafts like mine. My knives are unique in ethos and looks, but I’m also confident they are great working tools.’

It takes Tim 20 hours to make one of his knives and he currently makes around six a week, each costing between £100 and £300.

Tim says finding the material is relatively easy and that foraging alone on a wild Scottish beach is therapeutic.

‘The process starts with collecting my materials,’ Tim said. ‘The NOx canisters come from the streets of Glasgow and London, and the plastic mainly from the beaches of Wigtownshire.

‘Everything needs a good clean and sort before I start forging. The canisters are flattened and then forge-welded into a billet with a core of high carbon steel (this is the only material that I buy).

‘From there a knife is forged, heat treated and ground all in my workshop. The plastic gets chopped up and hot injected into my handle moulds which are made from used aluminum beer cans.

‘Most of my handles are made from various types of polyethylene plastics, mostly from discarded fishing gear.

‘Sometimes an odd word on an item found on a beach gives a clue as to how far it’s travelled, from North Africa, North America and sometimes the other side of the UK.’

Visitors to this year’s Spring Fling Open Studios Weekend (25-27 May), involving 104 studios across Dumfries and Galloway, can go to Tim’s forge in Newton Stewart and see how he is contributing to this movement.

To find our more visit www.spring-fling.co.uk

Read more News stories here.

Subscribe to read the latest issue of Scottish Field.

TAGS