The Woollard & Henry paper mill has made an indelible mark on the Scottish fabrication industry.

Ernest Woollard’s legacy is invisible – unless you hold it up to the light.

The engineering company he founded in Dyce, Aberdeen, Woollard & Henry, is now one of only five firms worldwide which know the secrets of the watermark.

The watermark was invented by paper-makers at Fabriano in Italy during the 13th century. Paper was originally made by hand in wooden vats filled with water and rags. The vatman scooped up the pulped rags with a wirecloth tray, and as water drained through the mesh it left behind a thin layer of pulp which dried to form paper.

The pattern of the wire left an indelible mark – hence ‘watermark’.

Nowadays, paper is made in a continuous process on a Fourdrinier machine, where wet pulp travels around a series of cylinders and gradually becomes more paper-like. One of those is the Dandy Roll, a hollow cylinder clad in wirecloth which is embossed with a pattern.

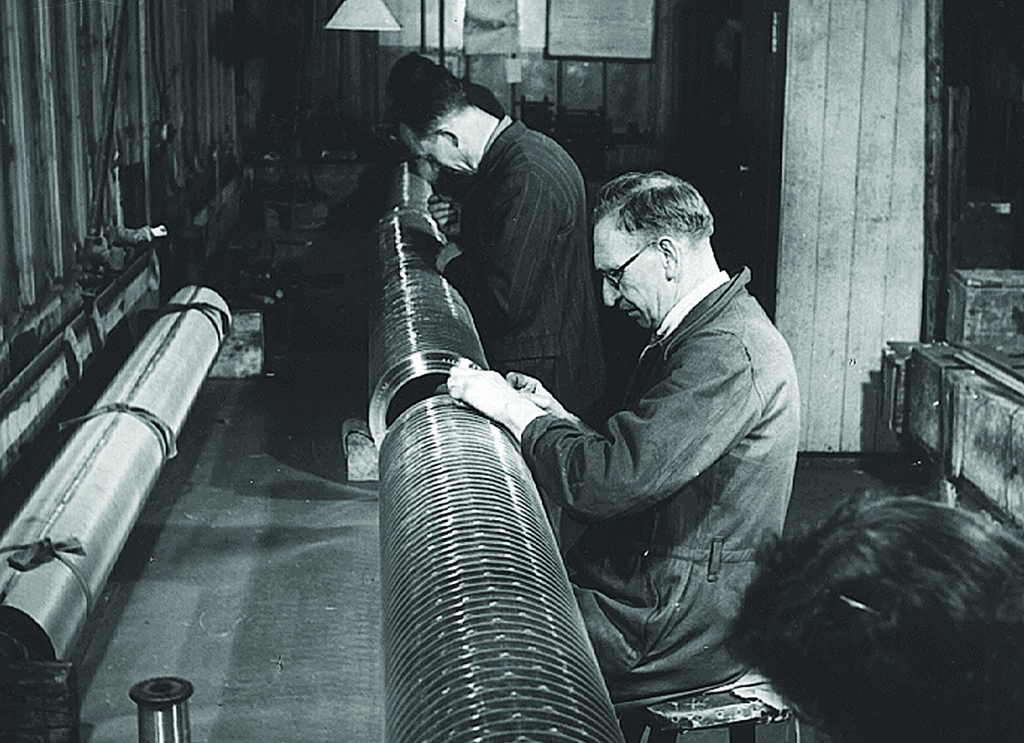

Craftsmen from the 1950s

This mesh or ‘lay’ acts as a sieve and also impresses the watermark into the damp fibres. Vatman, dandy, lay: every trade has its own language. Some, like the jargon of weaving or sailing, have filled our everyday speech. Others, such as paper-making, kept their vocabulary largely to themselves: hence other exotic terms such as potcher, halfstuff, quire and hollander.

‘Dandy’ is an old Scots name, as in Walter Scott’s character Dandie Dinmont, yet it remains a mystery why it was adopted by papermakers.

The Dandy Roll was patented in 1830 and as Woollard & Henry’s managing director Fred Bowden explained, each one is custom-made. Nowadays, the firm’s rolls can measure up to 9 metres wide and 1.8 metres in diameter, and watermark designs include script, symbols and cameos of famous people such as Winston Churchill, Lady Diana and Robert Burns.

The firm was established in 1873 by Ernest Woollard, who had a background in engineering and spotted an opportunity to supply the local paper-making industry.

It became Woollard & Henry in the 1930s, when Dick Henry added his business acumen. Fred Bowden explained that it grew after the war, and the export trade gradually became more important as Scotland’s paper industry shrank.

Originally based on the same site as Stoneywood Mill, Woollard & Henry relocated to a purpose-built factory at Stoneywood Park in the 1980s.

Just as the firm is unique in Britain – they took over their last rivals Green Son & Waite a few years ago – Stoneywood is the last surviving paper mill in the north east and still relies on its neighbour’s expertise in watermarking machinery.

The Queen and Duke of Edinburgh meet the company’s directors

The Woollard connection ended when Ernest’s granddaughter left the firm in the 1980s, and when Alastair Henry retired in 2002, he put the company up for sale. For a time it looked like it would pass into history, along with other parts of the north east’s paper industry, but Woollard & Henry was saved by becoming an employee-owned cooperative.

The firm has since diversifi ed beyond dandy rolls into other paper-making machinery, such as cylinder moulds, vacuum systems and AccuSteam, which sprays steam onto paper to improve its quality.

W&H has also put its skill working with stainless steel and phosphor bronze to use by fabricating The Frog, a personnel carrier which transfers crew between offshore platforms and boats.

That’s less of a departure than it sounds, because the harsh environment of the North Sea is matched by the aggressive atmosphere of steam and chemicals in a paper mill.

As the Plastic Age draws to a close we’ve begun to fall back on paper and cardboard, which are infinitely recyclable – in the same way that Woollard & Henry drew upon their ingenuity to develop new markets.

Their name might not be well known to Aberdonians, but their skills are evident if you know where to look – rather like a watermark.

TAGS